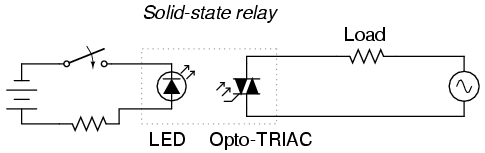

Solid-state relays

As versatile as electromechanical relays can be, they do suffer many limitations. They can be expensive to build, have a limited contact cycle life, take up a lot of room, and switch slowly, compared to modern semiconductor devices. These limitations are especially true for large power contactor relays. To address these limitations, many relay manufacturers offer "solid-state" relays, which use an SCR, TRIAC, or transistor output instead of mechanical contacts to switch the controlled power. The output device (SCR, TRIAC, or transistor) is optically-coupled to an LED light source inside the relay. The relay is turned on by energizing this LED, usually with low-voltage DC power. This optical isolation between input to output rivals the best that electromechanical relays can offer.

Being solid-state devices, there are no moving parts to wear out, and they are able to switch on and off much faster than any mechanical relay armature can move. There is no sparking between contacts, and no problems with contact corrosion. However, solid-state relays are still too expensive to build in very high current ratings, and so electromechanical contactors continue to dominate that application in industry today.

One significant advantage of a solid-state SCR or TRIAC relay over an electromechanical device is its natural tendency to open the AC circuit only at a point of zero load current. Because SCR's and TRIAC's are thyristors, their inherent hysteresis maintains circuit continuity after the LED is de-energized until the AC current falls below a threshold value (the holding current). In practical terms what this means is the circuit will never be interrupted in the middle of a sine wave peak. Such untimely interruptions in a circuit containing substantial inductance would normally produce large voltage spikes due to the sudden magnetic field collapse around the inductance. This will not happen in a circuit broken by an SCR or TRIAC. This feature is called zero-crossover switching.

One disadvantage of solid state relays is their tendency to fail "shorted" on their outputs, while electromechanical relay contacts tend to fail "open." In either case, it is possible for a relay to fail in the other mode, but these are the most common failures. Because a "fail-open" state is generally considered safer than a "fail-closed" state, electromechanical relays are still favored over their solid-state counterparts in many applications.

From a different site:

Opto-coupled devices

Opto Triacs and Solid State Relays.

Devices that are used in the control of high voltage/high power equipment need to have good electrical insulation between their high voltage output and low voltage input. Relying on a layer of silicon a few atoms thick to provide the required insulation, is not really an option in such conditions. When faults occur (and they are more likely to do so in high power circuits) the results can be catastrophic, not only to the circuit components but also to the users of such equipment. Physical isolation (meaning that there is no electricalconnection at all between the input and output) is what is needed. Fortunately there are easy and cheap solutions to this problem. High power circuits are often controlled by "Opto−electronic devices" such as Opto−Triacs, Opto−Thyristors and Solid state relays.

The materials used in the manufacture of Triacs and SCRs, like any semiconductor device, are light sensitive. Their conduction is changed by the presence of light, that´s why they are normally packaged in little chunks of black plastic. However, if a Light Emitting Diode is included within the package that shines its light on a light sensitive semiconductor housed in the same I.C. package, it is possible to control a high power device in response to a very small input current through the LED, without having an electrical connection between the two.

The Opto Triac.

This is the principle used in Opto−Triacs and opto−SCRs, which are readily available in Integrated circuit (I.C.) form, and do not need very complex circuitry to make them work. Simply provide a small pulse at the right time to the Light Emitting Diode in the package. The light produced by the LED activates the light sensitive properties of the Triac or Thyristor gate and the power is switched on. The isolation between the low power and high power circuits in these optically connected devices is typically several thousand volts.

Figure 1. The Opto Triac.

Solid State Relays.

Solid state relay is similar to the opto coupled devices already mentioned, but using power MOSFET transitors as the switching device. Solid State Relays (SSRs) can replace many types of low power electromechanical relays.

It uses opto−coupling to provide complete electrical isolation between its low power input circuit and its high power output circuit. When the output switch is "open" (MOSFETs off) it has a nearly infinite resistance, and a very low resistance when "closed" (MOSFETs conducting heavily). It can also be used to switch either AC or DC currents.

Figure 2. The Solid State Relay.

A typical circuit of an SSR is shown in Figure 2. A current of about 20mA through the LED is sufficient to switch on the output MOSFETS. The (infra red) light from the LED falls on the Photovoltaic unit, which comprises 25 silicon diodes. Each diode produces 0.6V to give the 15V gate potential needed to turn on the MOSFETS. Figure 2 represents a basic example of a SSR, in this case the Siemens LH1540T SSR, manufactured as a 6 pin DIL package. Many more complex chips are available that act as double pole, Normally Closed (NC), Normally Open (NO), and Change−over relays with a wide variety of extra facilities. SSRs are also manufactured in a range of output voltages and current ratings, with a range of package types ranging from small surface mount components through complex multi pin chips and large heavy current examples, for rack mounting in electrical control cabinets. Information on SSRs can be found by searching for Solid State Relays on manufacturers websites such as Infineon Technologies or at semiconductor suppliers such as RS Components (opens in a new window)

Download a datasheet for the LH1450 SSR from Datasheet.org.uk

Figure 3. Using a Solid State Relay chip for switching A.C. or D.C.

Figure 3 shows alternative methods of using the LH1540T SSR for switching either DC or AC power supplies.

Testing opto coupled devices.

The LED in these devices will operate with a forward voltage of between 1V and 2V, the presence of a higher voltage across the LED would indicate an open circuit. LEDs are difficult to test reliably with the diode range of an ohmmeter, since the voltage used is often too low to turn them on. If a correct voltage reading is found across the LED and the output device is not switched on then the IC should be changed. THE WARNINGS APPLYING TO MAINS VOLTAGES ALSO APPLY TO THESE COMPONENTS WHERE THE OUTPUT IS SWITCHING A HIGH VOLTAGE.

ANY WORK ON MAINS POWERED CIRCUITS MUST BE DONE WITH THE MAINS SUPPLY FULLY DISCONNECTED AND ANY CHARGE STORING (e.g. CAPACITORS) COMPONENTS DISCHARGED UNLESS THIS IS ABSOLUTELY UNAVOIDABLE

If you have not been trained in the safe working pactices that are essential for work on these types of circuit DON'T DO IT! The voltages and currents used in these circuits can kill!

Images on them:

No comments:

Post a Comment